What is Back Purging and Why is it Important for a Motorcycle Exhaust?

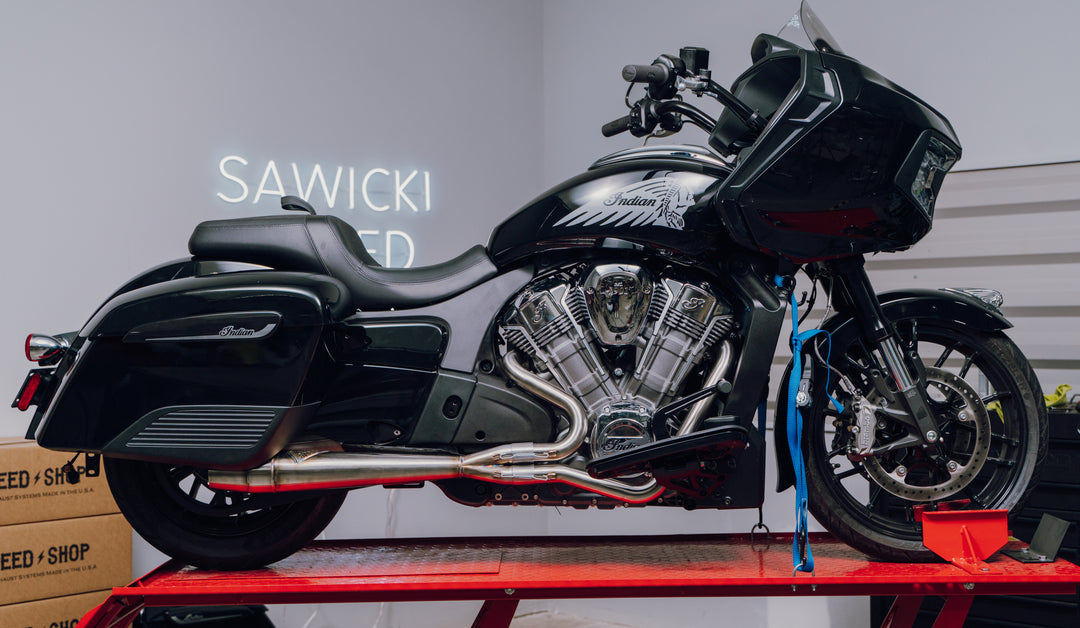

For many Harley-Davidson or Indian Motorcycle riders, the exhaust system is one of the most crucial components for both performance and sound. But behind every high-quality, high-performance Sawicki Speed exhaust lies exceptional craftsmanship and precision welding techniques like back purging. This often-overlooked process plays a key role in creating exhaust systems that not only enhance your bike's performance but are also built to last a lifetime. But what is back purging, and why does it matter?

What is Back Purging?

Back purging is a specialized welding technique that involves removing oxygen and other reactive gases from the back of a weld joint in order to protect the weld from contamination. This is done by replacing the air with an inert gas, such as argon, which acts as a protective barrier during the welding process.

When it comes to motorcycle exhausts, this process involves running the inert gas inside the tubing as the welds are performed. Back purging creates a clean, smooth interior weld surface that is free from impurities like oxidation, ensuring both structural integrity and optimal conditions for exhaust flow.

The Gas

Sawicki Speed welders use argon, an inert gas, in back purging procedures. This reduces the possibility of oxidation during welding.

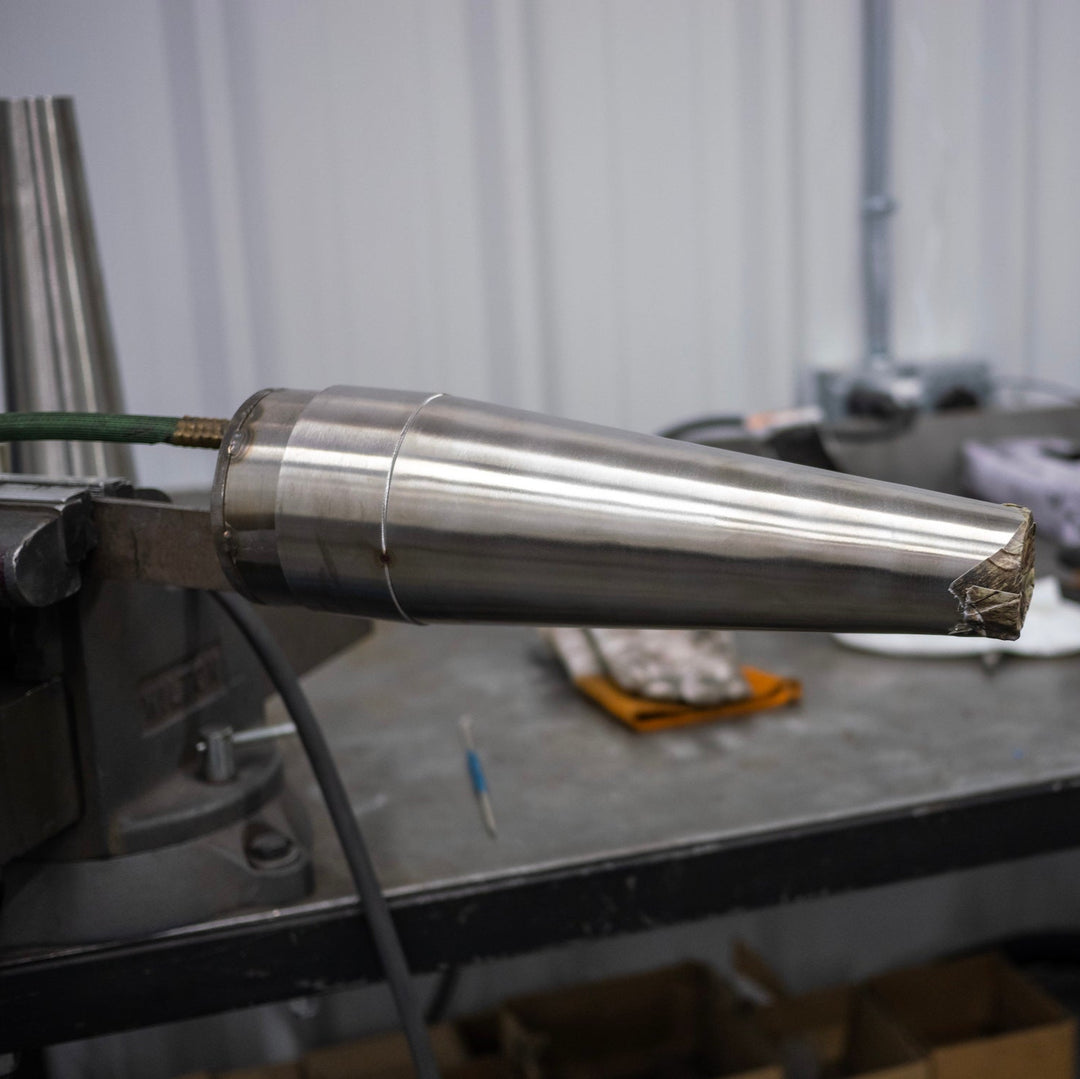

The Setup

The welder sets up the piece on a special stand, with the argon gas hose running out from the left side. The open end is taped off but not completely sealed.

The Weld

The welder can now perform the weld while the gas is flowing through the interior of the pipe. (Note: our welders always wear gloves and other safety gear while working – this photo was taken to demonstrate the process)

Why is Back Purging Important in Exhaust Manufacturing?

Exhaust systems go through a lot—they endure high temperatures, pressure changes, and the erosive effects of exhaust gases. Back purging ensures the weld stand up to these challenges while maintaining efficiency and durability. Here's how:

1. Smoother Welds Improve Airflow

A motorcycle’s exhaust system heavily relies on smooth airflow for optimal performance. Back purging enables this by eliminating the uneven back side of a weld joint. When the inside of the tubing is flush and free of “sugaring” (ridges and bumps on and around the weld surface), exhaust gases can flow more freely, improving overall efficiency and performance. Riders experience smoother throttle response, reduced exhaust restriction, and often, a more pronounced exhaust note.

2. Prevents Oxidation

Without back purging, oxygen inside the tubing can react with molten metal during welding, leading to oxidation. Oxidation causes weak, brittle welds that are prone to cracking or failure over time. With back purging, the inert gas prevents this reaction, resulting in strong, durable welds that stand up to the stress of riding.

3. Stronger, Longer-Lasting Exhaust Systems

Exhaust welds created without back purging are not just weaker—they're also more likely to have tiny holes in the welds that can compromise structural integrity. By using back purging, welders can produce cleaner, defect-free welds, ensuring the exhaust system is reliable for years to come.

4. Better Resistance to Cracking

The constant vibration and temperature changes in motorcycle exhaust systems put welds under significant stress. Welds made with back purging techniques are more resilient to cracking because they are less porous, smoother, and stronger. This means extra peace of mind for riders who push their bikes to the limit.

Welded Without Back Purging

This is an example of a weld that was done without back purging. Notice the prominent ridges that are more likely to disrupt airflow.

Welded With Back Purging

This is an example of a back purged weld. Notice the weld line is much smoother than in the other example.

Why Some Skip Back Purging (But Why We Don’t)

Some manufacturers and fabricators skip back purging because it adds time, cost, and requires additional equipment like inert gas supplies. While this saves money upfront, it compromises the exhaust's airflow, durability, and long-term performance. Skipping this crucial step can result in welds that are more likely to fail over time, impacting both the rider's experience and the bike's performance.

At Sawicki Speed, we don’t cut corners. Every single 2-into-1 performance exhaust system we craft for Harley-Davidson and Indian Motorcycles is back purged to achieve the highest possible standard. It’s an investment in quality, durability, and rider satisfaction that we believe pays off tenfold.

Why Back Purging Matters to Riders

For motorcycle enthusiasts, understanding how exhaust systems are made can give you an appreciation for how these components contribute to your bike's performance. Back purging isn’t just a technical term, it’s a promise of quality, durability, and performance. When you choose an exhaust system from Sawicki Speed, you’re not just getting a better-looking or better-sounding exhaust, you’re getting a product built with integrity and designed to perform. Whether you’re cruising the open highway or tearing up the track, back purging ensures that your exhaust is working as hard as you are.

Elevate Your Ride with Sawicki Speed

For us at Sawicki Speed, back purging isn’t just about making our exhaust systems perform better – it aligns with our commitment to excellence and craftsmanship. We’re proud to be a “Made in the USA” company, holding ourselves to the highest industry standards to deliver premium products. Back purging exemplifies that commitment, representing the very best practices in welding and manufacturing.

Our mission is to give riders the tools they need to optimize their bikes with performance-focused, American-made exhaust systems. From expert curation to utilizing advanced welding techniques like back purging, our goal is to deliver only the best to fellow riders. Want to experience the difference? Explore our lineup of high-performance 2-into-1 exhaust systems and see why riders around the world choose Sawicki Speed.